Seaweed (coconut) dry production line

Description of Equipment

1. Equipment simple description

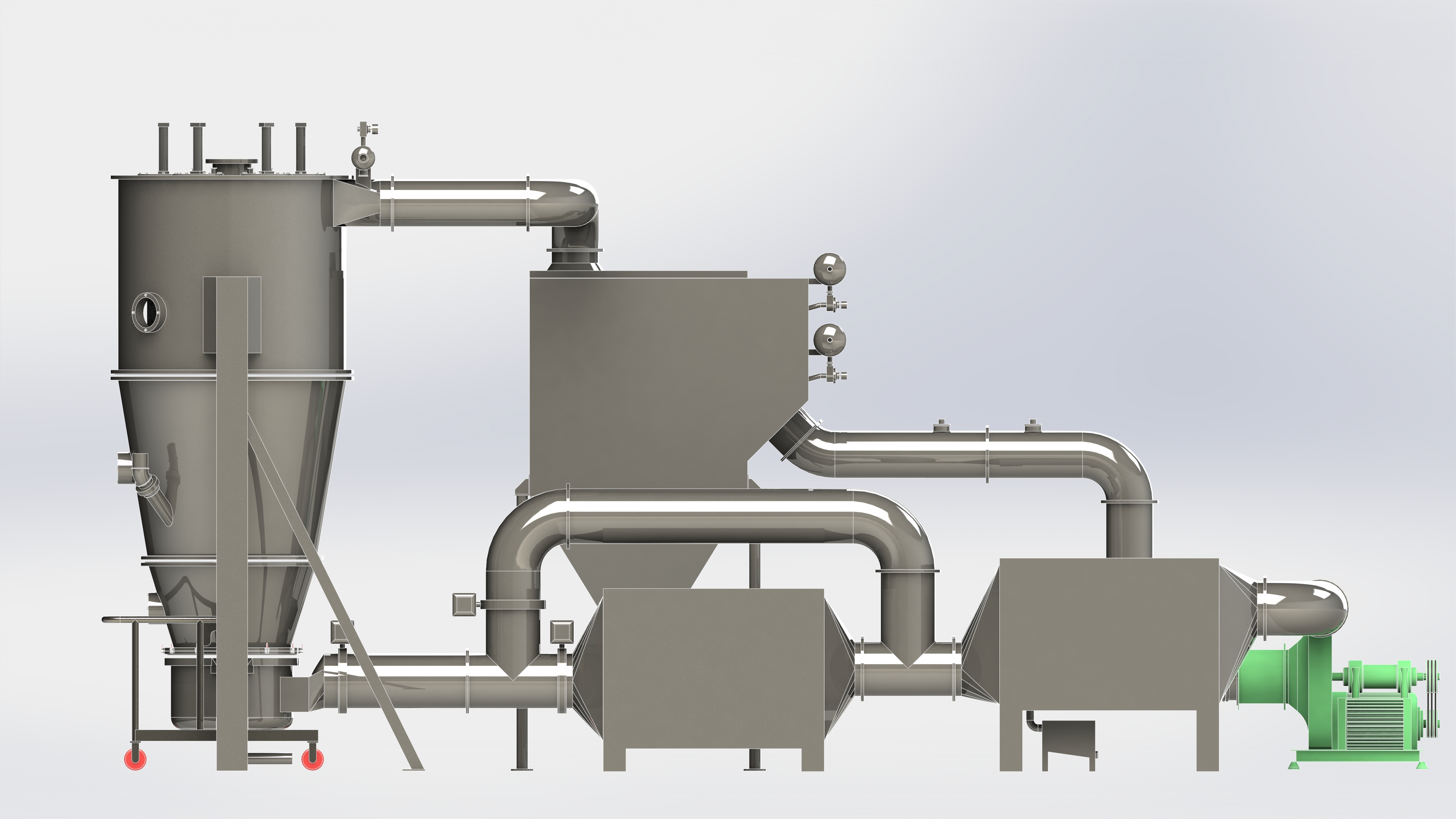

The mesh belt dryers consists of material feeding , material distributing ,air filtering ,heating and cooling ,main machine ,drive system, bypass filtering , material discharge system, online cleaning ,air exhausted and dehumidifying system ,control system and so on .

When working, the material entered into material distributor from the feeding system, and then go into dryer. when material contacted with the hot air gone through the mesh, the water is evaporated, and then material is dry.

2.Drying Chamber

A) The main body for the mesh belt dryer is drying chamber, it consists of shell ,frame, insulation ,maintenance door and so on ;

B)The both sides of drying chamber are all set maintenance doors on it .it is easy to see the inside performance of the mesh belt dryer by the maintenance door . the door lock adopts the pressed-rod structure,the surface of it is very beautiful . the door gasket is silica rubber ;

C). the structure of the drying chamber is frame type . the inside wall is made of 1.5mm SUS304 ; the outside wall is made of 1.2mm SUS304. The welds inside the dryer should be polish. The exterior plate edges are folded to make sure that the exterior is not defective. The inner part of the skeleton is made of carbon steel with 80x80x3;

D) Insulation for the drying chamber:the insulation material are 80mm silica aluminum.

3.Hot air circulating system

The Equipment is divided into a number of hot air circulation units.

under the action of hot air circulation fan at the top, the air is heated by the side duct after steam radiator. and then go through from the bottom of the net belt t and material, take material moisture away. The partial wet hot air is discharge by the dehumidified fan ,meanwhile , the partial fresh air are implemented to low the humidity content of circulation fan.

The hot air temperature can be automatic controlled by the temperature sensor , steam control valve and temperature controller .

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai