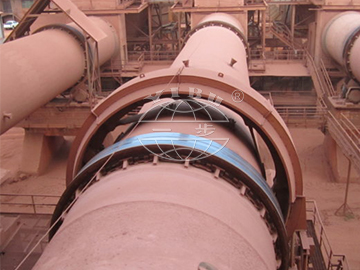

titanium dioxide production line

There

are two kinds of methods for producing titanium dioxide: Chlorination method

and Sulfuric Acid method. Each method has its own advantages. Compared with the

Chlorination method, the Sulfuric Acid process is more mature, and the

technical difficulty is relatively small, and the raw material is easy to

obtain. This method can produce many kinds of products. However, the disadvantages

are the long process flow and the large amount of waste discharge. For the Chlorination

method, it has the short process flow and less waste discharge, but the

technical difficulty is high, currently, it can only produce rutile type

products. The world's natural rutile ore storage is limited, if we produce the

titanium from the raw material, the pollution will be transformed to the

upstream progress. So from the world development trend of titanium dioxide, Chlorination

may not replace Sulfuric Acid method, these two kinds of production methods

will coexist for a long time.

Therefore, we choose the Sulfuric Acid method as the production method.

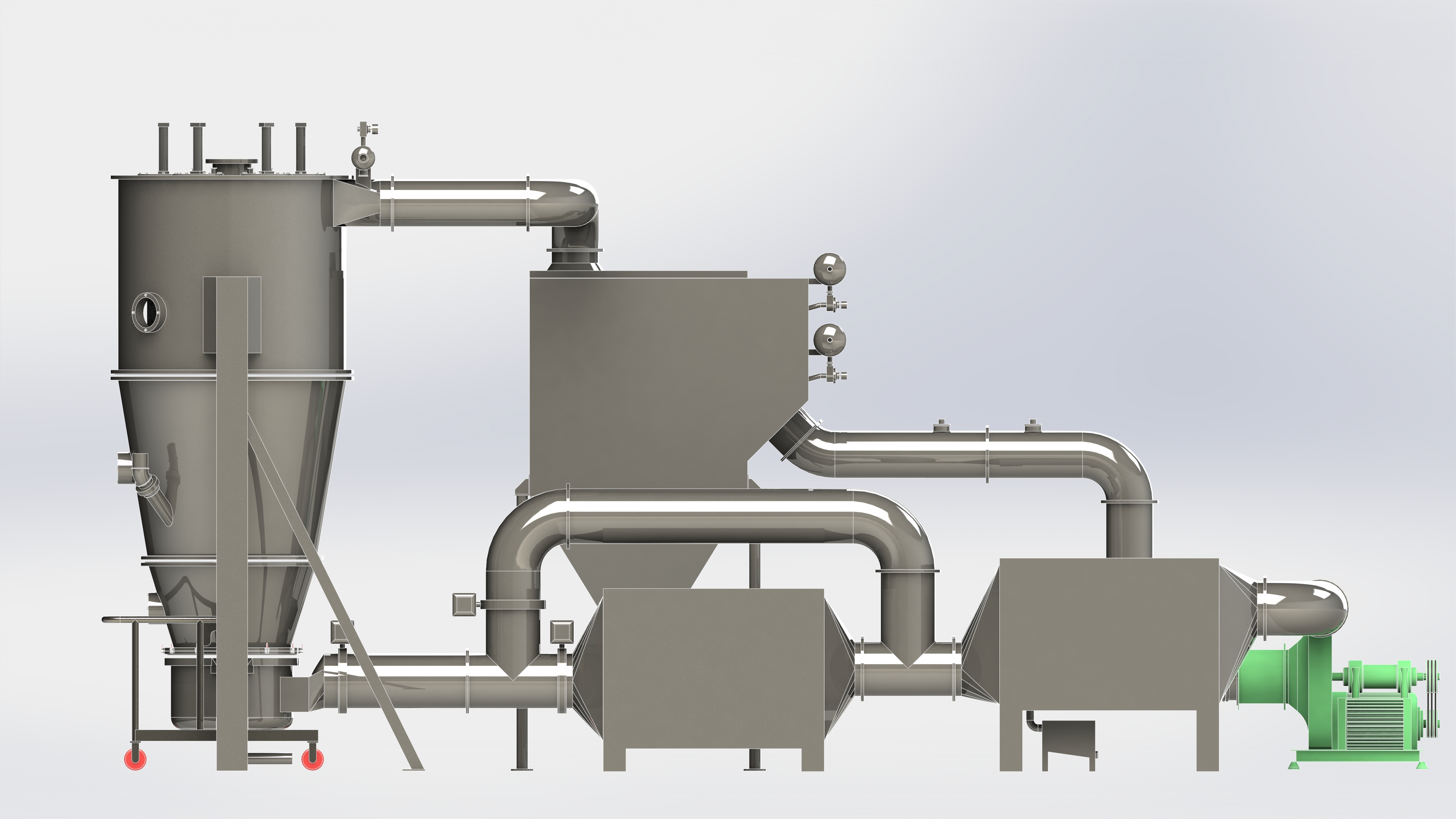

The raw materials for the production of sulfate process titanium dioxide has two kinds: one is the high grade titanium rich material (such as acid soluble titanium slag), the other is a cheap titanium concentrate, the two kinds of raw materials can meet the needs of the production of titanium dioxide products. Foreign manufacturers will take the acid soluble titanium slag as raw material, while, due to the high price of sulfate process titanium dioxide acid soluble titanium slag supply, domestic manufacturers still take titanium concentrate as their raw material.

This design takes the titanium concentrate as raw material, the concentrate of tio2 is 47%. The tio2 concentrate in one ton of finished rutile titanium white powder product is 930kg. To eliminate the sales pressure of by-product ferrous heptahydrate, we can adopt the combination of ore and slag as the material line, use some high acid-soluble titanium slag together with the titanium concentrate, this production method can not only solve the problem of ferrous heptahydrate, but also protect the non-renewable resources. Therefore, this design will choose the titanium concentrate as the raw material, and adopts ore and slag mixture method, at the same time, we may adjust the raw material according the market condition of ferrous(when the sales of ferrous heptahydrate is poor, we may use the combination of titanium concentrate and high titanium slag to reduce the by-product of ferrous heptahydrate.

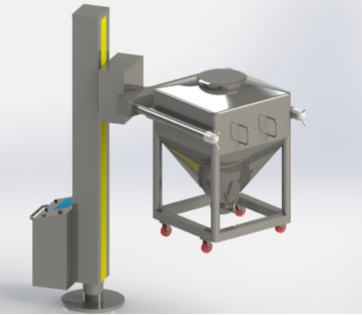

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai