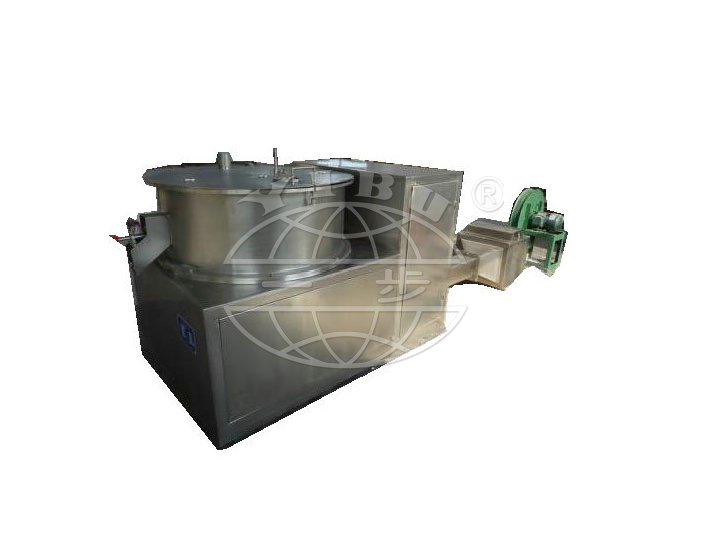

PGL-B Series Spray Drying Granulator

PGL-B Series Spray Drying Granulator

Product Description

Spray Drying granulator machine makes use of spray and fluid bed technology to realize mixing, granulation and drying in one container. The fluidized powder is wetted by the spaying the extract until agglomeration occurs. As soon as the size of the granule is reached . spraying is stopped and the wet granules are dried and cooled .

Spray agglomeration moves very small, powder particles in the fluidized bed where they are sprayed with a binder solution or suspension. Liquid bridges are created that form agglomerates from the particles. Spraying continues until the desired size of the agglomerates is reached.

After the residual moisture in the capillaries and on the surface has evaporated, hollow spaces are created in the granulate while the new structure is solidified throughout by the hardened binder. The lack of kinetic energy in the fluidized bed results in very porous structures with plenty of internal capillaries. The usual size range of the agglomerate is from 100 micrometers to 3 millimeters, while the starting material can be micro-fine.

Features

1.Integrate spraying, drying fluid granulating in one body to realize granulating from liquid in one step.

2.Using the process of spraying, it is particular suitable for micro auxiliary raw materials and heat sensitive raw materials. Its efficiency is 1-2 times than the one of fluidized granulator.

3.The final moisture of some products can reach 0.1%. It is equipped with powder returning device. The rate of granule forming is more than 85% with 0.2-2mm of diameter.

4.The improved inner roller multi-flow atomizer can treat the liquid extract with 1.3g/cm3 of gravity.

5. Currently , the PGL-150B , it can process 150kg/batch of material .

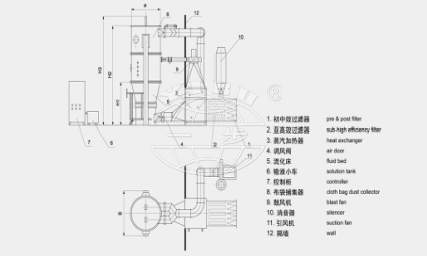

Schematic of installation

|

Spec |

PGL-3B |

PGL-5B |

PGL-10B |

PGL-20B |

PGL-30B |

PGL-80B |

PGL-120B |

||

|

liquid extract |

min |

kg/h |

2 |

4 |

5 |

10 |

20 |

40 |

55 |

|

|

max |

kg/h |

4 |

6 |

15 |

30 |

40 |

80 |

120 |

|

fluidization capacity |

min |

kg/batch |

2 |

6 |

10 |

30 |

60 |

100 |

150 |

|

|

max |

kg/batch |

6 |

15 |

30 |

80 |

160 |

250 |

450 |

|

specific gravity of the liquid |

g/cm3 |

≤1.30 |

|||||||

|

volume of material vessel |

L |

26 |

50 |

220 |

420 |

620 |

980 |

1600 |

|

|

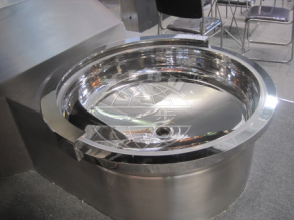

diameter if vessel |

mm |

400 |

550 |

770 |

1000 |

1200 |

1400 |

1600 |

|

|

power of suction fan |

kw |

4.0 |

5.5 |

7.5 |

15 |

22 |

30 |

45 |

|

|

power of auxiliary fan |

kw |

0.35 |

0.75 |

0.75 |

1.20 |

2.20 |

2.20 |

4 |

|

|

steam |

consumption |

kg/h |

40 |

70 |

99 |

210 |

300 |

366 |

465 |

|

|

pressure |

Mpa |

0.1-0.4 |

||||||

|

power of electric heater |

kw |

9 |

15 |

21 |

25.5 |

51.5 |

60 |

75 |

|

|

compressed air |

consumption |

m3/min |

0.9 |

0.9 |

0.9 |

0.9 |

1.1 |

1.3 |

1.8 |

|

|

pressure |

Mpa |

0.1-0.4 |

||||||

|

operating temperature |

°C |

automatically regulated from indoor temperature to 130°C |

|||||||

|

water content of product |

% |

≤0.5% (depends on the material) |

|||||||

|

rate of product collection |

% |

≥99% |

|||||||

|

noise level of machine |

dB |

≤75 |

|||||||

|

weight |

kg |

500 |

800 |

1200 |

1500 |

2000 |

2500 |

3000 |

|

|

dim. of main machine |

Φ |

mm |

400 |

550 |

770 |

1000 |

1200 |

1400 |

1600 |

|

|

H1 |

mm |

940 |

1050 |

1070 |

1180 |

1620 |

1620 |

1690 |

|

|

H2 |

mm |

2100 |

2400 |

2680 |

3150 |

3630 |

4120 |

4740 |

|

|

H3 |

mm |

2450 |

2750 |

3020 |

3700 |

4100 |

4770 |

5150 |

|

|

B |

mm |

740 |

890 |

1110 |

1420 |

1600 |

1820 |

2100 |

|

Weight |

kg |

500 |

800 |

1200 |

1500 |

2000 |

2500 |

3000

|

|

Sample on model choice : Suppose that are 120kg liquid extract (include 30% solid )and 60kg seed II in one vessel ,from I and II,we can get theoretical product amount M=mI+mII=120kgx30%+60kg=96kg ,working time T=120kg/30kg/h=4h ,from the parameter table we can find that the fluidization amount is inside the standard loading range .if we require two batches in one duty time ,PGL-30B is ok.

Pharmaceutical industry: tablet, capsule granule, granule of Chinese medicine with on or low sugar

Foodstuff; cocoa, coffee, milk powder, juice of granule, flavoring and so on.

Other industries: pesticides, feed, chemical fertilizer, pigment, dyestuff and so on.

Options

Product charging by lifting machine.

Product charging by vacuum transfer system

Printer

WIP system

-

PGL-B Series Spray Drying Granulator

-

PGL-B Series Spray Drying Granulator

-

PGL-B Series Spray Drying Granulator

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai