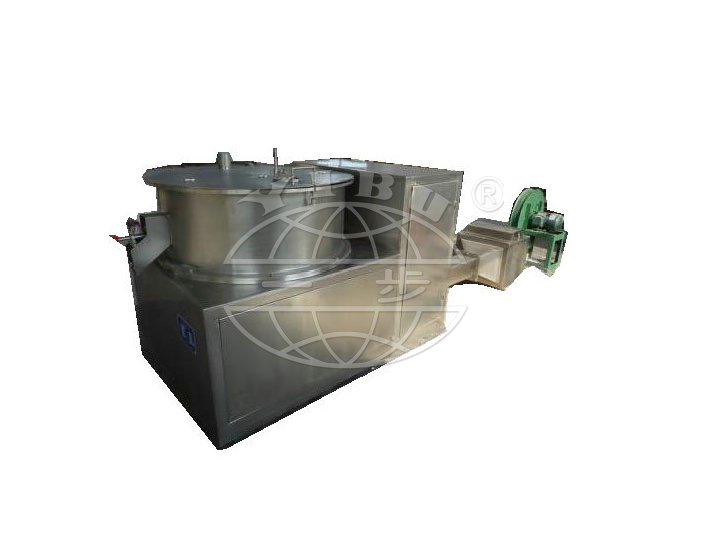

DLB Series Multi-function Granulator &Coater

DLB Series Multi-function Granulator &Coater

(Lab-type picture showing)

Product Description

DLB Series Multi-Function Granulator & Coater is a new type of solid ingredients/ material preparation equipment, that integrates granulating, coating, fluidizing and rotating granulating together. It is mainly applicable for granulating, pill making and coating in pharmaceutical, chemical, foodstuff and so on industries, such as granules to be pressed to tablets, or to be filled into capsules, granules for other Chinese and Western Medicine, solid drinks, especially controlled release capsules and granule.

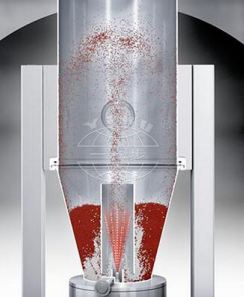

Spray coating can be performed – usually in batch processing – in all fluidized bed systems. For some coating applications, a continuous process is also available. The film material is applied as a solution, suspension or melt. Caution should be taken here that no liquid bridges form during application in order to avoid undesirable agglomeration.

When coating using a solution or a suspension, the liquid serves to transport the solids to the surface of the particles. When a melt is used for coating, in contrast, the coating material is one-hundred percent spreadable. YIBU technologies permit an optimal retention time of the particles in the coating zone. This assures outstanding coating qualities.

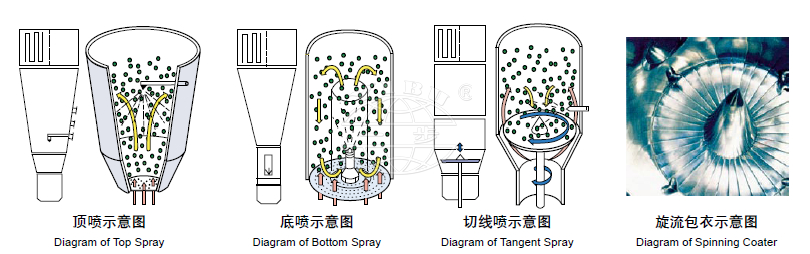

Coating can take place as top spray, tangential spray, bottom spray or rotor process, depending from which direction the particles are being sprayed. These methods can all be performed in a single, modern fluidized bed system. Customized for your needs.

Function

▪ Tangent spray technique: pelletizing, covering, coating

▪ Top spray technique:granulating

▪ Bottom spray technique:coating

Tangent spray technique:the material in the fluid bed is pushed upward by the hot air flow, it will do regular spin rolling movement in the specially designed container with the influences of centrifuge of the rotary plate, centripetal force of material container, the air flow back and the gravity. The liquid sprayed at a tangent direction make the material into core of pills, which are coated by powder from tangent spraying to get required tighten fine pellets.

Top spray technique: the material in the fluid bed forms upward. Flowing state pushed by the hot air flow, then combined into granules gradually by the liquid sprayed from upward, and irregular granules will be gotten after drying.

Bottom spray technique: the material is pushed upward from the bottom of the flow leading pipe by hot air flow and sprayed back, and coating liquid is sprayed from bottom of the flow leading pipe ,and coated onto the materials moving in the same direction to achieve the coating purpose.

Application

Mixing: For various kinds of fluidizable materials, such as powder, granules, micro-granule etc. Because of multi-dimensional movement (horizontal, tangent and radial direction), the mixing effect is very good.Granulating: Spray adhesive onto powder to produce granules with various diameters.

Coating: Efficient for to coat powder, granules and microgranules.

Thermal Material Coating: Suitable for coating powder, granules and micro-granules with thermal wax.

Spray Drying: Spray liquid or suspension onto powder so they should be dried.

Cooling: This equipment might also be used for cooling powder or granules.

Technical Paramenters

|

Spec |

DLB- |

5 |

15 |

30 |

60 |

120 |

300 |

500 |

|

Max working capacity(L) |

Top spray |

22 |

45 |

100 |

420 |

620 |

1100 |

2000 |

|

Bottom spray |

15 |

35 |

90 |

400 |

550 |

900 |

1600 |

|

|

Electric heater power (kw) |

21 |

27 |

45 |

81 |

135 |

234 |

315 |

|

|

Range of temperature (°C) |

0-120automatically regulated |

|||||||

|

Consume of steam (kg/h) |

60 |

100 |

180 |

220 |

366 |

600 |

1000 |

|

|

Power of fan (kw) |

5.5 |

11 |

15 |

22 |

30 |

55 |

75 |

|

|

Amount of compressed air (m3/min) |

0.6 |

0.6 |

0.9 |

1.1 |

1.3 |

3.0 |

4.0 |

|

|

Weight (kg) |

1450 |

1800 |

2600 |

3450 |

4000 |

6500 |

8000 |

|

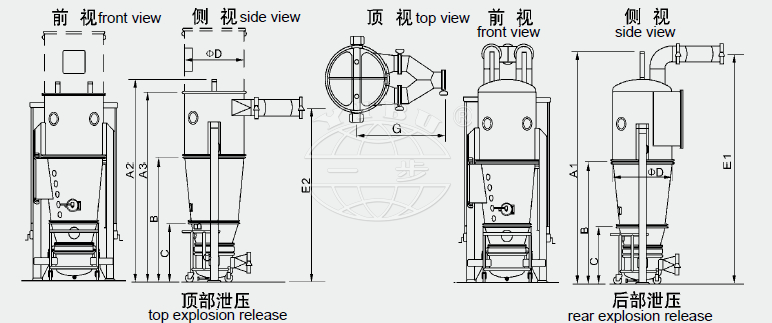

Overall dimensions

Parameters

|

sizes |

A1 |

A2 |

A3 |

B |

C |

ØD |

E1 |

E2 |

G |

|

5 |

3210 |

3210 |

2810 |

2140 |

920 |

500 |

3260 |

2610 |

740 |

|

15 |

4060 |

4060 |

3660 |

2280 |

970 |

800 |

4100 |

3410 |

970 |

|

30 |

4400 |

4400 |

4000 |

2520 |

1130 |

1200 |

4600 |

3750 |

1420 |

|

60 |

4800 |

4800 |

4400 |

2900 |

1180 |

1400 |

5000 |

4100 |

1620 |

|

120 |

5100 |

5100 |

4700 |

3000 |

1380 |

1500 |

5300 |

4400 |

1620 |

|

300 |

5760 |

5760 |

5490 |

3465 |

1840 |

1800 |

6500 |

5090 |

1990 |

|

500 |

6630 |

6630 |

6360 |

4145 |

2145 |

2700 |

7590 |

5960 |

2960 |

Options

- Product charging by lifting machine.

- Product charging by vacuum transfer system

- Printer

- WIP system

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai