YPG series Pressure spray (cooling) Dryer

YPG series Pressure spray (cooling) Dryer

Test

Because of different products have different drying technologies and particle rules, there is no single type of the spray drying machines that meet all kinds of different requirements. Now spraying is still regards as a kind of technology. The test is the base of correctly choosing the types. The machine equipped by the "YIBU" Company is used specially for the carry out the technological test of the materials. This kind of practical manner makes that we have completed many turn-key projects, such as: detergent powder, polymerized resin, white carbon,Mn3O4,soybean milk, lipase, sea cucumber Chinese traditional medicine and etc.

This equipment combines drying and granulating two functions together.

The needed ball granule with certain size and ratio can be got in accordance with requirements of process to adjust pressure, flow, and size of atomizing hole..

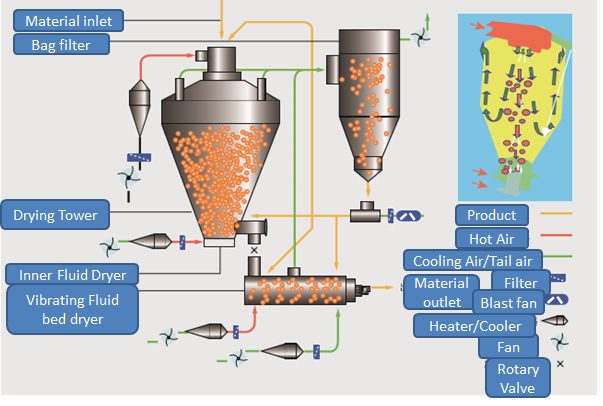

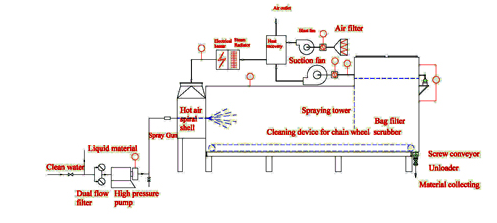

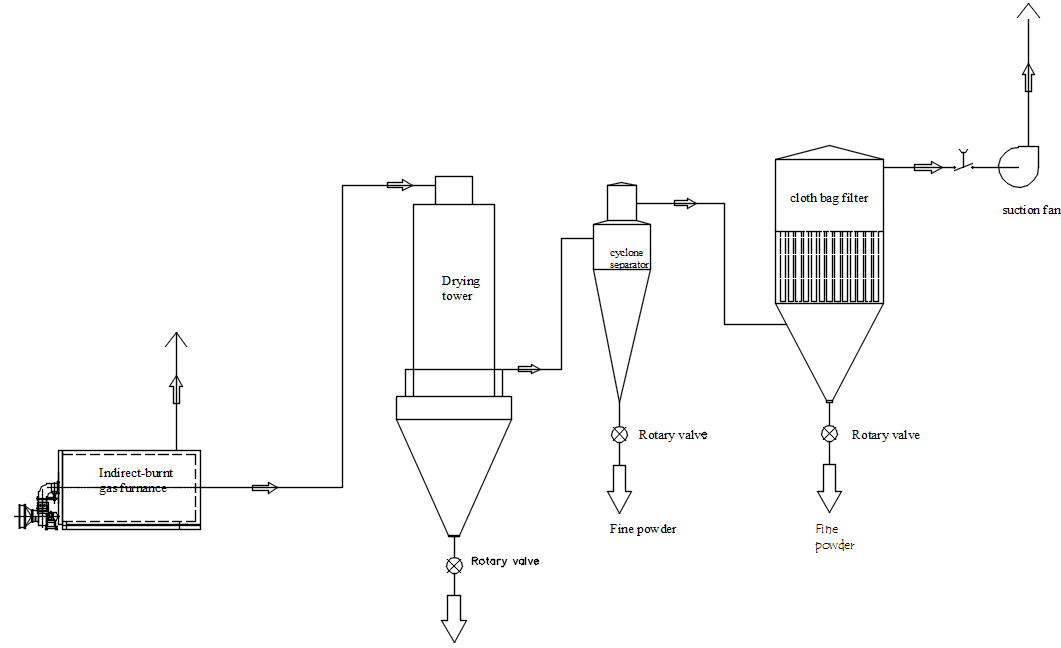

The working of the pressure spray dryer as follows:

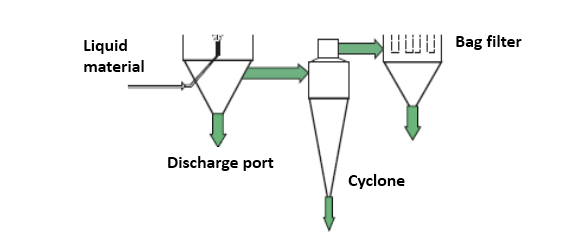

the liquid of raw material is pumped in through diaphragm pump. The liquid of raw material can be atomized into tiny droplets. Then it gathers with hot air and falls off. Most parts of powder material will be collected from the the outlet of the main tower bottom . for the fine powder , we will still continuously collect them by the cyclone separator and cloth bag filter or water scrupper . but it should depend on the material property .

For the pressure spray dryer , it simply has bellow system :

1.Air inlet system it consists of air filter (such as Pre&post filter&Sub-high efficiency filter and high efficiency filter) , air heater (such as electrical heater ,steam radiator ,gas furnace and so on ) draft fan and relative air inlet duct .2.Liquid delivery system it consists of diagraph pump or screw pump ,material stirring tank and relative pipe .

3.Atomizing system : pressure pump with inverter

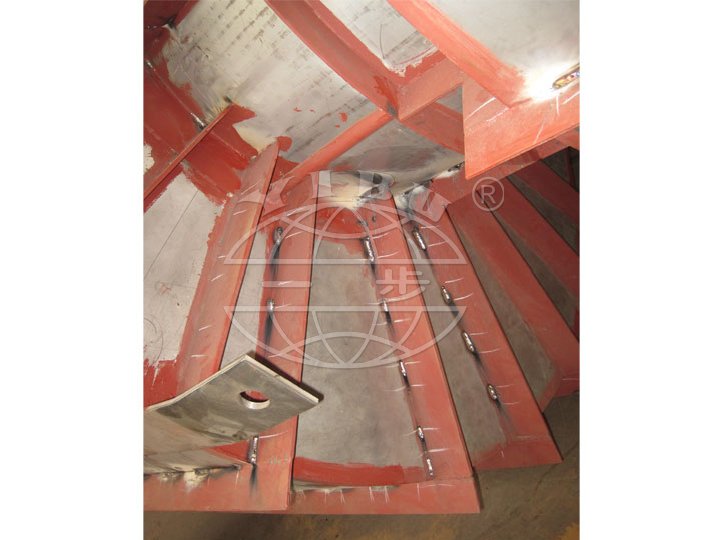

4.Main tower. it consists of the conical sections , straight sections , air hammer , lighting device , manhole and so on .

5.Material collecting system. it consists of cyclone separator and cloth bag filter or water scraper .this parts should be equipped based on customer needs .

6.Air outlet system . it consists of suction fan ,air outlet duct and post filter or High efficiency filter.(for the filter chose , it is based on the customer request.)

The tower body, pipes and separator of set where will contact with the product are made of AISISUS304 or AISISUS304L or AISISUS316L or AISISUS316. There is enough layer of heat preservation between inner and outer case of the drying tower body. The filled material is fine glass cotton. The tower body we also equipped with observation door, sight glass, lamp-house and control meters and instruments that is controlled and displayed through electric control panel.

1.high collecting rate

2.no stick onto the wall

3.fast drying

4.energy saving

5.high efficiency

6.especially applicable for heat heat sensitive material.

7.For the heating system for the machine , it is very flexible. we can configure it based on the customer site conditions such as steam ,electricity , gas furnace and so on , all of them we can design it to match our spray dryer.

8.Control system has more choices, such as push button, HMI+PLC and so on

Applications

Food Industry:Fatty milk powder, protein, cocoa milk powder, subsitute milk powder ,egg white (yolk), food and plant ,oats ,chicken juice, coffee ,instant dissoluble tea ,seasoning meat ,protein ,soybean ,peanut protein , hydrolysate and so forth .Sugar ,corn syrup ,corn starch ,glucose .pectin ,malt sugar , sorbic acid potassium and etc.

Medicine: Traditional Chinese medicine extract ,ointment ,yeast, vitamin ,antibiotic, amylase ,lipase and etc .

Plastics and resin : AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly-chloroprene and etc.

Detergent :common washing powder ,advanced washing powder ,soap powder ,soda ash ,emulsifier ,brightening agent ,orthophosphoric acid and etc.

Chemical industry :Sodium fluoride (potassium ), alkaline dyestuff and pigment ,dyestuff intermediate, Mn3O4, compound fertilizer ,formic silicic acid ,catalyst, sulphuric acid agent ,amino acid ,white carbon and so on .

Ceramic : aluminium oxide ,ceramic tile material ,magnesium oxide ,talcum and so on .

Other : Calmogastrin, hime chloride , stearic acid agent and the cooling spray .

- For the main electrical components , we have international brand choices such as ABB , Siemens or Schneider or others

- For the material for the machine , we have choices onAISISUS304 , AISISUS304L, AISISUS316,AISISUS316L,carbon steel and so on .

- For the control system , we have choices on push button, PLC+HMI and so on .

- We can design the explosion-proof system for our spray dryer based on the customer request.

- For the fitting system for the spray dryer, we can supply it. such as feeding system , pneumatic conveying system and so on .

- For the heating system for the machine , it is very flexible. we can configure it based on the customer site conditions such as steam ,electricity , gas furnace and so on , all of them we can design it to match our spray dryer.

- If without heating system , it can as a cooler to make particle with cooling air.

Technical parameters

|

Spec |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

2000~10000 |

|

Water evaporation capacity Kg/h |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

2000~10000 |

|

Overall dimension(ф*H)mm |

1600×8900 |

2000×11500 |

2400×13500 |

2800×14800 |

3200×15400 |

3800×18800 |

4600×22500 |

|

|

High-pressure pump pressure Mpa |

2-10 |

|

||||||

|

Power Kw |

8.5 |

14 |

22 |

24 |

30 |

82 |

30 |

|

|

Inlet air temperature ℃ |

300-350 |

|

||||||

|

product water contents % |

less than 5 percent, and 5 percent can be achieved. |

|

||||||

|

collection rate % |

>97 |

|

||||||

|

electric heater Kw |

75 |

120 |

150 |

When the temperature is lower then 200, the parameters should be calculated according to the practical condition. |

|

|||

|

electricity + steam Mpa+Kw |

0.5+54 |

0.6+90 |

0.6+108 |

|

||||

|

hot air furnace Kcal/h |

100000 |

150000 |

200000 |

300000 |

400000 |

500000 |

1200000 |

|

Attention to order

1.Liquid name and property: solid contents (or water contents), viscosity, surface tension and PH value.2. Dry powder density residual water contents allowed, particle size, and maximum temperature allowed.

3. Output: shift time daily.

4. Energy that can be supplied: steam pressure, electricity properly, fuel of coal, oil and natural gas.

5. Control requirement: whether or not the inlet and outlet temperatures should be controlled. Powder collection requirement: whether it's necessary to use cloth bag filter and the requirement of the environment of the exhausted gas.

6. Other special requirements.

-

YPG series Pressure spray (cooling) Dryer

-

YPG series Pressure spray (cooling) Dryer

-

YPG series Pressure spray (cooling) Dryer

-

YPG series Pressure spray (cooling) Dryer

-

YPG series Pressure spray (cooling) Dryer

-

YPG series Pressure spray (cooling) Dryer

- 2019-06-15 > P-MECH CHINA 2019 YIBU BOOTH NO: N3B10a

- 2019-04-15 > YIBU will attend the 57th CIPM Exhibition held in Changsha in Hunan province

- 2018-12-28 > Actived carbon particle mesh belt dryer made for Ingrevity

- 2018-03-10 > big spin flash dryer and spray dryer delivery to pakistan and Italy customer on time

- 2017-12-29 > two sets high speed centrifugal spray dryers and three sets of drum dryre delivered to Indonesia

- 2017-08-24 > one set of LPG-100 spray dryer is delivered to America

- 2017-08-24 > Five layers mesh belt dryer is sucessfully delivered to Manila(Philippines)

- 2017-04-05 > Exhibition interpack 2017 in Dusseldorf In Germany

- 2016-11-23 > The 18th International Exhibition in Moscow

- 2016-10-14 > THE 16TH AGROCHEMEX 2016 in shanghai